How and why tungsten electrodes are sharpened

Wiki Article

Tungsten electrodes are very popular in the world. They are widely used when working with aluminum, stainless steel, and various non-ferrous metals.

To obtain high-quality welds, we recommend using a tungsten electrode and shielding gas. Experienced craftsmen use a wide variety of methods and techniques in their work. It is not enough to know and use only one welding method.

There are quite interesting and not complicated ways to increase work efficiency. One of them is sharpening electrodes. Below we will tell you why this technology exists and is widely used, and how it is recommended to sharpen a tungsten electrode.

GENERAL INFORMATION

Tungsten is considered one of the most refractory metals used in the production of electrodes. Tungsten begins to melt at a temperature of 3000 degrees.

In everyday work with a welding machine, such temperatures are usually not used. Based on these data, it is accepted to consider tungsten electrodes as non-melting. When exposed to high temperatures, they actually retain their original shape, size and diameter.

However, there are ways to change the initial shape and size of the tungsten electrode. And, this is exactly what can be achieved when striking the arc or when creating the seam itself. The electrode can gradually shrink when in contact with the metal. This process can be the root cause of non-fusion of the metal.

“There are simple but very effective ways to deal with this undesirable moment. Namely, to increase the level of penetration, the master sharpens the tungsten electrode. This, in turn, creates optimal professional seams.”

HOW CAN I SHARPEN AN ELECTRODE?

There are known methods that are used. One of them is sharpening tungsten electrodes using a special paste, this method is considered chemical. Also widely used by craftsmen is the mechanical method. Tools will be needed for it.

For this method, a hand-held machine is used, but more often craftsmen use a machine for sharpening tungsten electrodes. The use of these methods leads to an increase in the efficiency and quality of the work performed. There are two forms of sharpening most commonly used by working craftsmen.

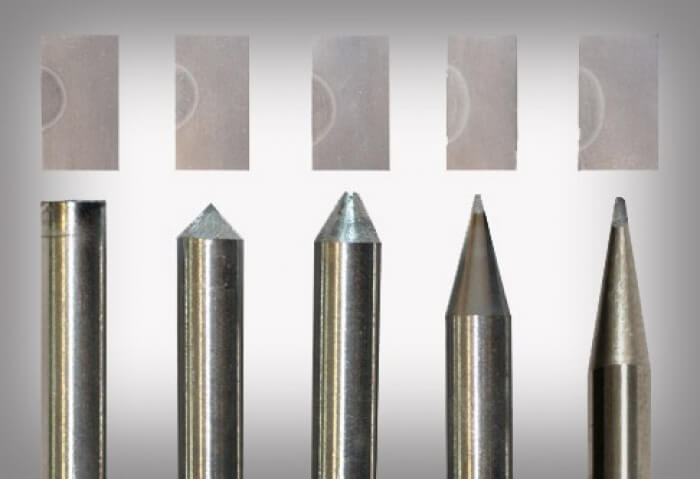

Sharpening can be in the form of spherical or conical sharpening. Spherical sharpening is more often used for working with a welding machine with constant, uninterrupted current.

Some craftsmen have noticed that there are no big and significant differences between working with tungsten electrodes with different forms of sharpening, however, differences do exist. Especially in cases of professional work. Here is the formula: Ø*2

Let's assume that the diameter of the electrode is 3 mm, then the length of the pointed part will be 6 mm. This way you can calculate your own diameter.

Masters recommend that after sharpening, slightly blunt the end of the resulting electrode by running it along a hard surface. An important feature is the sharpening angle of your electrode. For it, you need to choose and match the size of the welding current supplied.

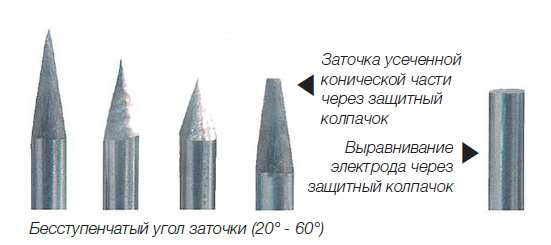

“If the master works at low speeds of the supplied welding current, then an angle of 10-20 degrees will be acceptable for sharpening. A more suitable angle is an angle of 20 degrees. If an angle of 2 or 40 degrees is required, then it is recommended to use a slightly higher level of the supplied current than low.

In cases where the master works with a high current, the resulting sharpening angle can be from 40 to 120 degrees. But experienced masters do not recommend making the core more than 90 degrees.

SUMMARY

We have discussed in detail the issue of tungsten rod sharpening. We have talked about existing sharpening methods, nuances and features of the work. We hope that the information received will serve as your first step in the development and advancement of understanding what tungsten sharpening is.

Source: Zvarka.info

Report this wiki page